Meat and Poultry Processing

Processing Tech

Processors continue to search for better stunning methods and slaughter equipment.

Read More

Meat Science Review

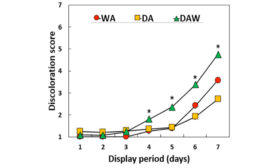

Effects of dry aging on color and oxidation stabilities of beef loins

December 16, 2016

Processing Tech

Update on use of vision systems in protein processing

Processors are incorporating 'vision'-ary process innovations.

Read More

Raider Red Meats: A double major

Raider Red Meats is succeeding not only as a high-end meat processing business but also as an educational tool for its student employees.

Read More

Processing Technology

Conveyor cleanliness

Conveyors go a long way in enhancing worker welfare and reducing inefficiencies in meat and poultry plants, but they also are sources of potential food safety risks.

Read More

Meat Science Review

Definition of factors that impact fresh pork tenderness

October 11, 2016

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing