Tech Topics: Food Safety

How electrostatic intervention technology can help processors maximize resources and food safety

Processors can now utilize electrostatic technology in place of immersion dips and traditional in-line spray systems.

Photo courtesy Birko

With foodborne illnesses estimated to cause 48 million infections and 128,000 hospitalizations annually in the United States (CDC), it is crucial that processors take every precaution necessary to prevent the growth and spread of harmful pathogens. Due to the high risk associated with foodborne illness and meat products, processors may find themselves using more time and resources on sanitation practices than necessary, ultimately hurting their sustainability initiatives and bottom line.

Between conserving major resources, controlling costs, and preventing the spread of foodborne illness, meat processors need additional resources and technology to help prioritize food safety and operational efficiency equally. Fortunately, beef, pork and poultry processors don’t have to choose between prioritizing food safety and optimizing resource use. As intervention application techniques continue to advance, processors can now successfully utilize electrostatic technology in lieu of immersion dips and traditional in-line spray systems.

Traditional applications of antimicrobial agents

To help eliminate the presence of harmful bacteria often found in raw meats and poultry products, such as Salmonella, Listeria and E. Coli, antimicrobial intervention chemistries are instrumental. These antimicrobial agents are commonly applied in the form of a spray or dip system. While many food safety partners continue to develop innovative blends of antimicrobial agents, the chemistries are only effective if applied properly.

Antimicrobial dip systems involve completely immersing the raw products in a solution containing the antimicrobial chemistries for a specific length of time. This method helps processors achieve high coverage of the antimicrobial agent on each product but requires high volumes of chemicals. Furthermore, the dip solution often needs to be replaced or continually filtered to prevent it from becoming oversaturated with contaminants from the meat. While effective for reducing the microbial load on meats, dip systems can generate a lot more waste when compared to other methods of antimicrobial application, hurting a processor’s bottom line.

Another popular antimicrobial application system for meat processors is in-line spray systems. This method utilizes spray zones to distribute a fine mist of the antimicrobial agent to the surface of each product as it moves along the production line. To avoid excessive waste, in-line spray systems are commonly automated to apply a very specific amount of solution. While this antimicrobial application method may offset high costs by conserving resources, it can still result in overspray and may struggle to achieve the same full 360-coverage that immersive dips can.

So how can processors get the best of both worlds? Electrostatic technology paired with leading-edge equipment is the key

Automated electrostatic technology

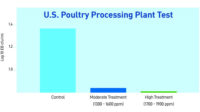

The intention for electrostatic intervention technology has been to improve transfer efficiency by applying opposite charges to the meat products and the antimicrobial agent. When the electrostatic charge is applied to the intervention chemistries, the solution becomes positively charged. This results in the disinfecting agent becoming more attracted to the negative charge of the meat, providing a more thorough coverage.

But electrostatic technology is often not enough on its own. To achieve full coverage, processors can combine electrostatics with cutting-edge equipment designed to slowly rotate meat products as they move along the production line. A gradual rotation helps expose all surfaces of the product, resulting in an even distribution of the antimicrobial agent, effectively reducing harmful microorganisms that could contribute to foodborne illnesses.

With much of the meat processing industry requiring significant resources to operate, identifying ways to save on resources and create efficiencies is crucial. Processors should aim to balance their need for water, chemicals and energy with their sustainability and food safety goals.

By combining these technologies, meat processors can achieve the same, if not better, transfer efficiency in less time compared to that of traditional application methods. Because the antimicrobial agents are distributed evenly and accurately, the intervention application process requires minimal amounts of water and chemicals—helping processors reduce time, waste and cost of operations. Furthermore, combining electrostatic technology with an enclosed rotating chamber can help reinforce worker safety because there is less chance of overspray.

Overall, electrostatic technology is a highly effective approach that can offer numerous benefits when combined with the right equipment. Processors looking to safeguard their products and improve operations may want to consider how electrostatics can reduce their environmental impact, improve their bottom line, and keep them competitive in an ever-demanding market.

Continuing innovation

As the meat processing industry continues to prioritize sanitation, food safety, and sustainability, processors and food safety partners are constantly seeking ways to improve efficiency and reduce costs. With the emergence of new technologies, it is now possible to apply antimicrobial agents with greater precision, overcoming the limitations of traditional methods. However, the industry still faces challenges in reducing risk, liability and production costs.

By investing in research and development, the meat processing industry can drive innovation and maintain its commitment to public safety, while producing high-quality products. In doing so, processors can keep pace with evolving regulations and consumer demands while improving their bottom line. Through embracing new technologies and practices, the industry can build a more sustainable future and continue to meet the growing demand for safe, healthy and affordable products.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!