Home » Keywords: » antimicrobial interventions

Items Tagged with 'antimicrobial interventions'

ARTICLES

Tech Topics: Antimicrobial Sprays and Dips

Tech Topics: Food Safety

How electrostatic intervention technology can help processors maximize resources and food safety

Processors can now utilize electrostatic technology in place of immersion dips and traditional in-line spray systems.

Read More

Regulatory proposal heightens focus on antimicrobial sprays and dips

FSIS will release a proposal that Salmonella be considered an adulterant in not-ready-to-eat breaded and stuffed raw chicken products.

Read More

Tech | Supplier's Perspective

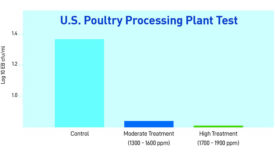

Electrostatic technology advances as antimicrobial intervention

Read MoreMeat Science Review

Mulitple-hurdle antimicrobial interventions and ground beef quality

August 9, 2018

Ingredients

The clean-label trend's impact on antioxidant and antimicrobial ingredients

Driven by cleaner labels: The clean-label trend has propelled the use of antioxidant ingredients and had an impact in the antimicrobial ingredient world as well.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.png?1647275041)