Food Safety

Food Safety

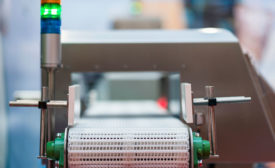

Sanitation in meat and poultry plants

Effective sanitizing is crucial for reducing bacterial threats in meat and poultry plants, but employee turnover and the intricacies in developing operational guidelines have an impact on outcomes.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing