Boston Sword & Tuna (BST) prides itself on being America’s one-stop shop for seafood. Founded in the 1970s by the Scola family, whose origins go back to fishing in Sicily, BST has grown to become one of the largest seafood distributors in the country. Their 50,000-square-foot, state-of-the-art facility handles a wide variety of whole and processed fish and seafood that go to supermarkets, restaurants, farmers markets, and more. To uphold their stringent quality and safety standards, BST installed three metal detectors from Mettler-Toledo Product Inspection to help protect consumers, customers, and partners as well as their brand reputation.

“Inspecting seafood is very challenging for most metal detectors,” said Phil Tripoli, maintenance manager at Boston Sword and Tuna. “Saltwater and ice, which are prevalent in our products, put out a magnetic field. You need a very specialized, premium metal detector to be able to reliably find metal contaminants without false rejects given this situation.”

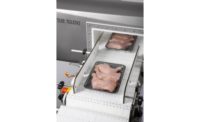

The Profile Advantage excels at identifying and rejecting every type of metal in even the most difficult applications. Compared to traditional single-frequency systems, this advanced inspection technology features multi-simultaneous frequencies to better discern changes due to the presence of metal versus changes within the product itself.

After purchasing one in 2020, Boston Sword and Tuna acquired two more of the inspection units in 2023, Tripoli said. BST now has a Profile Advantage installed on all three of their packaging lines to inspect final product quality. Each system features a large aperture to handle 10-pound corrugated cases of fresh and frozen product including cod, salmon, haddock, crab, swordfish, scallops, shellfish, and more.

“Our new inspection systems achieve great detection sensitivity, which is incredibly important considering the prevalence of metal items that can be concealed in seafood. Plus, these systems are consistent. They stay within our required specifications during long production cycles without any adjustments,” noted Tripoli. “We run calibration tests twice a day to confirm each metal detector is maintaining its high accuracy. They always hit the mark.”

If inspection systems at BST detect a potential problem, its conveyor belt automatically stops. “An operator puts the rejected case aside and then re-runs it through one of our other two metal detectors to see if it’s a calibration issue or a genuine reject – fortunately, both of these instances are extremely rare,” Tripoli said.

“We process a wide variety of seafood and, as you can imagine, fresh salmon is going to appear pretty different from frozen crab cakes to a metal detector,” Tripoli said. “We set up recipes for our different products to help us consistently produce the final product quality we need while minimizing false rejects to increase throughput and reduce labor.”

Mettler-Toledo’s metal detectors can store up to 100 different product recipes for fast recall during changeovers, while its “product clustering” capability minimizes the need for setting changes. When running a brand new product, the single-pass auto set-up routine quickly analyzes it, determines the ideal settings, and stores the data in the system’s memory.

“Recipe management is super simple on the Profile Advantage,” Tripoli said. “Adding a new product is intuitive – it becomes second nature once you’ve done it a couple of times. When we need to switch over to a different product recipe, it’s just a couple of taps on the control panel and we’re good to go.”

BST’s detection systems are password-protected, enabling the company to limit access to various capabilities as needed, Tripoli said

“This helps ensure that someone doesn’t make an incorrect change to a recipe. It gives us peace of mind to know that only a few people can make deep modifications,” he said. “Despite running almost 24 hours a day, six days a week, our metal detectors have been extremely dependable.”

In terms of cleaning and sanitation, Tripoli said a seafood plant is never going to be straightforward.

“Even though our metal detectors are handling packaged product and not raw, bulk fish, we still take our cleaning process very seriously,” he said. “We spray these systems down with water and sanitizing soap daily and then do a quick hand wash on parts as well. It’s really simple because they’re designed for sanitation and don’t have many nooks and crannies.”

Tripoli concluded, “We pride ourselves on putting out the highest quality product. Our inspection systems give us confidence that we are protecting our customers with the best metal detection technology on the market.”