Form-fill-seal continues its advance

Although some pouches, particularly retort pouches, are pre-formed and run on fill-seal systems, many pouched products are packaged on form-fill-seal (FFS) equipment.

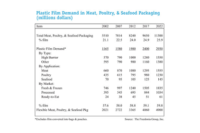

Consumers and brand owners favor flexible packaging, particularly pouches, for meat, poultry and seafood products. In fact, flexible packaging will continue to dominate the category and capture more than two-thirds (67 percent) of the U.S. market by 2020, according to a report published in June 2016 by Technavio, London, U.K.

The report, Meat Poultry and Seafood Packaging Market in the U.S. 2016-2020, attributes the growth to rising demand for meat, poultry and seafood products and explains, “Consumers prefer pouches as they are easy to use, are compact and lightweight, and are convenient while traveling.” Pouches also offer leak resistance, broad flexibility in design and size and can incorporate features such as barrier properties for extended shelf life and easy-open/reclose functionality. Pouches can serve as primary or secondary packaging. When used for secondary packaging, pouches often hold product in primary pouches, for example, frozen, single-serving fish fillets.

Although some pouches, particularly retort pouches, are pre-formed and run on fill-seal systems, many pouched products are packaged on form-fill-seal (FFS) equipment. Five types of FFS machines serve the meat, poultry and seafood market: horizontal (also called flow wrap); vertical; three-side-seal; double film (sometimes referred to as strip-pack or four-side-seal); and thermoform-fill-seal. Rectangular products such as jerky, meat bars and single-serving burritos are suited to horizontal FFS handling, which forms the film around the item. Vertical FFS machines can handle irregular shapes and products with discrete pieces such as meatballs, IQF shrimp or chicken parts. Products with discrete parts also may be packaged on three-side-seal or double film machines. Thermoform-fill-seal machines also rely on two webs of material and are suitable for bulkier products such as sliced lunch meat and may be directly integrated with a slicer.

On FFS machines the filling function may be manual or automated. Heat sealing remains the norm, but ultrasonic sealing is making inroads. Ultrasonic sealing can deliver cost, environmental and seal integrity benefits. A narrower seal area minimizes material usage to lower costs and provide a more sustainable, source-reduced package. Ultrasonic sealing also can improve seal integrity because seals can be formed even if there’s product contamination in the seal area.

Three words describe today’s FFS machines: faster, flexible and networkable. Speeds are higher with the fastest systems capable of outputs in excess of 200 pouches per minute. Downtime is shorter due to quick changeover features, tool-less adjustments, quick-thread film paths, color touchscreen control and easier-to-clean designs. If a problem arises, remote diagnostics expedite troubleshooting.

Flexibility makes it possible for operators to quickly set up and adjust the machine to run a new product, packaging material, package size and/or pouch style. Many machines easily switch among multiple pouch styles, e.g., pillow, gusseted and block-bottomed. Flexibility is further enhanced by the wide range of options available on many FFS machines, including package support with eject, fiber-optic print registration, hole punch, tear notcher, splicing table for seamless film changeover, jumbo film unwind, gas flushing, vibratory shakedown settling device and bag squeezers to reduce headspace air.

Networkability simplifies integration with up- and downstream systems as well as auxiliary equipment such as slicers, coders, labelers and checkweighers. NP

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!