Home » ready-to-eat

Articles Tagged with ''ready-to-eat''

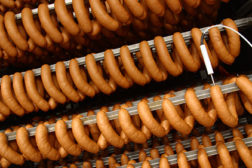

Food safety renaissance

Nearly three years after Maple Leaf Foods began to overhaul its food-safety culture, the company’s commitment to ensuring safe products has become the bedrock of its business.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing