Home » automation of processing lines

Articles Tagged with ''automation of processing lines''

The Spiral Bacon Smokehouse needs only two people for full operation.

Read More

Processing Tech

Benefits of automated cutting and deboning

Improved technology allows processors to benefit from today’s automated cutting and deboning operations.

Read More

Processing Tech

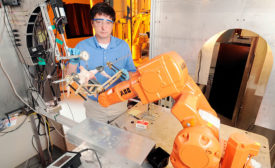

Rise of robotics in the meat processing industry

Automation is slowly but surely taking over manually demanding and repetitive jobs in the processing industry.

Read More

Guest Column

Optimizing inspection for meat processors

The state of robotics and automation.

Read More

Processing Tech

Automation in meatpacking plants: Manual transition

Cutting, deboning and trimming techniques mainly rely on worker skill, but automation is catching up, particularly in non-beef species.

Read More

Robotics and automation in meat and poultry plants

Robotics are on course to be mainstays in meat and poultry plants as the technologies become more dynamic and cost effective.

Read More

Cutting and deboning: Computerized butchers

Experiments with new cutting and deboning equipment aim to improve efficiencies, yields and worker safety.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing