2020 Food Safety Report | Supplier's Perspective | Standards

Are you ready for new FSIS performance standards?

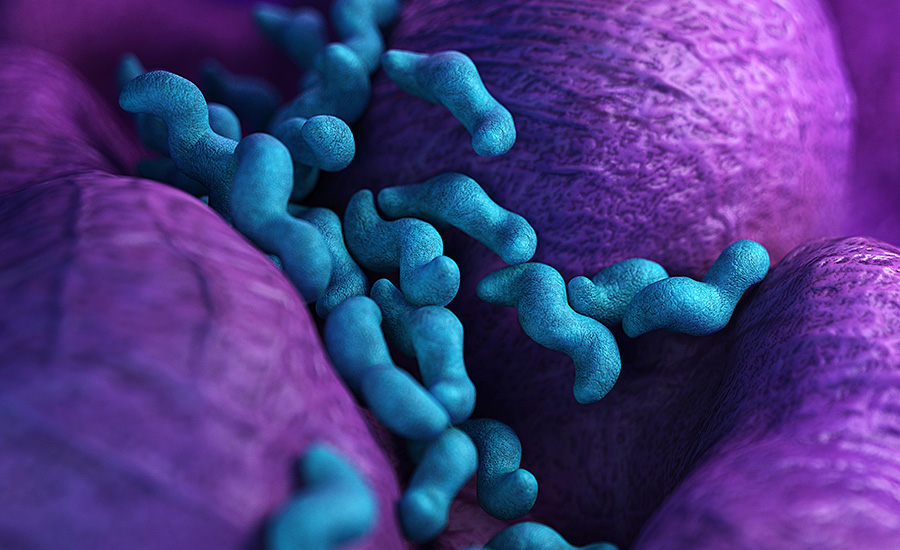

Controlling pathogens in meat and poultry processing is particularly challenging given the multiple points of contact. However, understanding the critical control points and intervention methods throughout a processing chain and how different technologies work in a multi-hurdle approach can help improve food safety by reducing, controlling or eliminating pathogens in the processing environment.

The increasing attention on new U.S. Department of Agriculture Food Safety and Inspection Service (FSIS) performance standards pending in both pork and poultry creates opportunities to reassess food safety plans to control the introduction and spread of pathogens. Implementing a multi-hurdle, multi-technology approach will be a key component to achieving the new performance standards.

Table of Contents:

Improving pathogen successes for meat and poultry

In recent years, the meat and poultry industries have strived to reduce, eliminate and control pathogens in their food products. But pending FSIS performance standards for Salmonella in pork and Campylobacter in poultry provide an opportunity for the industry to re-evaluate and implement new best practices to control pathogens. In order to achieve these standards, it will be important to establish a food-safety program with a true multi-hurdle and multi-technology approach. This improved multi-intervention approach to controlling pathogens is crucial to ensuring performance standards are being met and providing customers with safe products.

Data analytics

Before processors adopt these new performance standards, it is important to develop biomapping strategies to understand baseline pathogen loads for each processing facility. Knowing where you are today will help you put in place the proper protocols and targeted interventions needed to meet FSIS standards.

Monitoring the pathogen load on animals and birds coming into the plant helps establish a baseline level of product entering the facility. In-plant control measures can then reduce pathogen loads and prevalence. The lower the incoming load, the better the targeted interventions will work and the more likely the performance standards will be met.

Controlling pathogens

There are variety of food-safety products that processors can use to reduce, eliminate and control pathogens, including Salmonella and Campylobacter, during meat and poultry processing. Using broad-spectrum, post-harvest antimicrobials such as DBDMH (1,3-Dibromo-5,5-dimethylhydantoin) in a multi-hurdle, multi-technology approach is one way our studies have found to effectively control pathogens throughout processing.

Additionally, spraying DBDMH on meat and poultry carcasses has no negative or organoleptic effects on meat products. It is also safe for workers (established OSHA PEL), non-corrosive to many common alloys in commercial processing and not detrimental to wastewater systems.

Adding DBDMH into a food-safety program can help processers get ahead of impending FSIS meat and poultry performance standards and regulations and can help processors produce safe, high quality products for consumers. NP

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!