Protein Problem Solver

Oxygenation system helps Koch Foods cut wastewater BODs

BOD control with SOLVOX® oxygenation system from Linde

Dissolved air flotation (DAF) systems can separate 95 to 99 percent of fats, oils and greases (FOG) and total suspended solids (TSS) from organic wastewater — thus, they are an important treatment option for meat-processing facilities. Yet, DAF systems are less effective in lowering biochemical oxygen demand (BOD), which is sometimes necessary to reduce odors and meet municipal discharge requirements.

Against this backdrop, dramatic growth in demand of processed poultry from the fast-food industry created an opportunity for Koch Foods LLC to reevaluate its BOD wastewater-treatment process. The company’s poultry deboning facility in Morristown, Tenn., operates 24/7 and produces more than 70 million pounds of cut wings, and boneless chicken nuggets, tenders and breasts every year. That is about double the production rate of 2007, though over the next five years total process flow rates remained about the same (130,000 gpd). Therefore, mass loadings of organics in the effluents climbed — stretching demands on the DAF treatment system.

DAF units often use a coagulant and flocculent (polymer) ahead of the flotation unit, where solids are skimmed. Yet there are limits to these pretreatments, especially when organic solid loadings are high or hydraulic pressure dips.

Barry Calfee, Certified Environmental and Safety Compliance Officer (CESCO) at Koch Foods, contacted Linde, a global leader in environmentally friendly water-treatment solutions. The team estimated that costs for the proposed SOLVOX® oxygenation system would be about as low as an acid treatment system — yet SOLVOX would also offer significant environmental advantages.

“Sustainability is very important to Koch Foods as a leader in the food industry and a positive force in our local community,” Calfee says. “The Linde oxygenation system exceeded our expectations.”

Key to success of the new system is control of soluble BOD (sBODs). Although DAF pretreatment chemicals help reduce organic solids, sBODs require improved aerobic digestion. The SOLVOX oxygen booster system from Linde was designed and retrofitted for an existing 225,000 gallon aerobic equalization (EQ) tank feeding the DAF unit at the plant site.

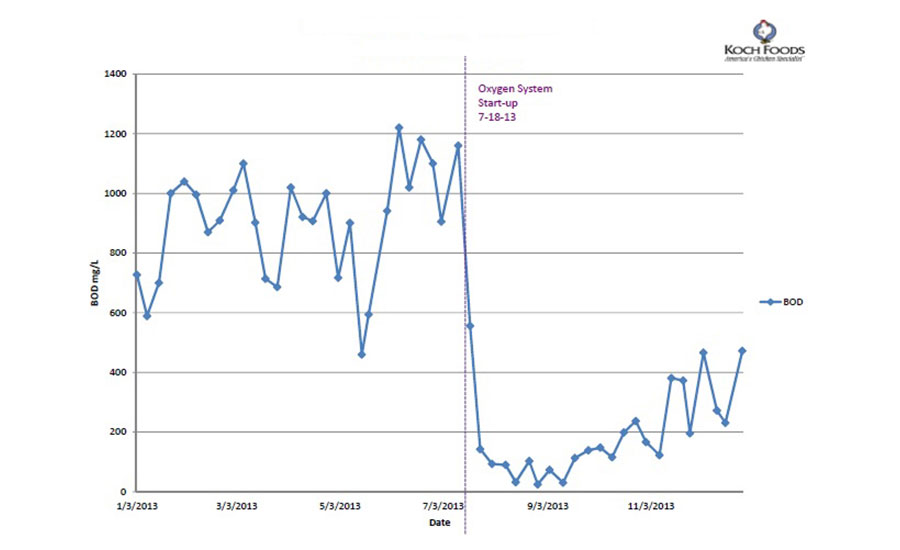

Aeration systems may follow DAF pretreatment and are almost always part of a publicly owned treatment facility (POTW). However, the high levels of sBODs that remained after screening for solids from the deboning facility meant the wastewater could easily use additional oxygen for aerobic metabolism, and the presence of the EQ tank before the DAF unit made O2 pretreatment both possible and cost effective. In the weeks after the SOLVOX system start-up, effluent BOD5 levels fell on the order of 90 percent. Even in cold weather, the system operates well within the anticipated reduction target of 50 percent BOD removal. (See BOD control graph, before and after the SOLVOX installation.)

The Linde solution for Koch Foods includes a 6,000-gallon liquid oxygen tank with vaporizer and control system. The SOLVOX control system delivers O2 through a gas sparger that feeds the oxygen-enriched water into a custom injection header inside the bottom of the EQ tank. NP

For more information about wastewater treatment options for the meat and poultry industry, visit http://www.lindewatertreatment.com/en/index.html, or contact Linde (www.lindeus.com), 800-755-9277.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!