Slicing Technology

Slicing finesse

Part of The National Provisioner’s 2014 Deli Report

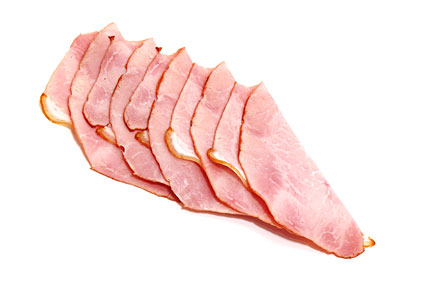

The slicing quality of meat and poultry items can be a feature used to appeal to consumers.

“The one thing that is universal, however, is that the meat needs to be pleasing to the eye,” says Paul Morin, Oscar Mayer’s research principal, R&D. “Consumers who purchase deli meats window-shop by looking through the package. Slice shape is critical.”

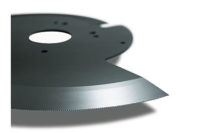

For Oscar Mayer’s meats, the company uses industrial versions of deli slicers with a rotating blade and mechanism that feeds the meat into the blade, Morin says. The features of a well-sliced protein for the company then vary depending on the product design. For example, one of the goals for Oscar Mayer’s conventional lunchmeat items is achieving intact slices. While for products like Oscar Mayer Carving Board, the company aims for irregular slices.

Maintaining the protein’s integrity is necessary to stand up to the strains of slicing. Variables such as formulation, slice thickness and condition of the slicer are some such strains, says Jeff Sindelar, extension meat specialist at the University of Wisconsin-Madison.

For example, thin slicing requires proteins to maintain well-defined slices. This is established by having a good gel formation and protein matrix, which stabilizes the meat system, Sindelar says. If good protein extraction doesn’t occur or strong gel set, then slicing problems — such as irregular slice thickness and tearing — can occur, he explains.

Other ingredients that are in the product — both meat and non-meat — can affect the sliceability of the product. Ingredients such as soy and whey protein can help add to the protein content, which can help improve sliceability, Sindelar says. Ingredients such as modified food starch can help manage moisture and also work in unison with the protein to help firm the product. This allows for better and faster slicing, Sindelar says. Different fats have different firmnesses, which can affect the sliceability of a product as well, he adds.

Another factor that affects the sliceability of meat and poultry is temperature.

“Temperature of slicing is very important so that the slicing isn’t done too cold, but cold enough so that the matrix is firmer,” Sindelar says. “The moisture is also in a more immobilized state.”

One of the challenges of slicing proteins is product waste while slicing at optimal production speeds. Product waste comes in the form of “chaff,” or little pieces of meat that fly off when the blade passes through, Morin says. Poor slices or slices that are too thick, too thin and partial pieces as well as the ends of the meat that can’t be sliced also contribute to waste.

Weight control is another challenge with the product needing to be at a specific weight for the package. Unintentional over and underweight causes product loss, Morin says.

From a technology standpoint, the industry is without one perfect slicing solution for all products. The industry custom tailors for its products that change compositionally, Sindelar says. “Any variation in the composition of the product, you can run into slicing problems,” he explains.

Some of the recent developments in slicing technology include new metallurgy that has improved the life and sharpness of the blade, Morin says. In addition, more computer controls enable more precise slicing.

“We expect the industry to see more changes that will help extend blade life and sharpness,” Morin says. “And further computerization will impact the process.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!