With film-based packaging (bags, peelable pouches, vacuum packs, zipper packs, etc.) having become so popular for meat, poultry and seafood products, upgrading or adding a packaging line often involves a form/fill/seal (FFS) machine.

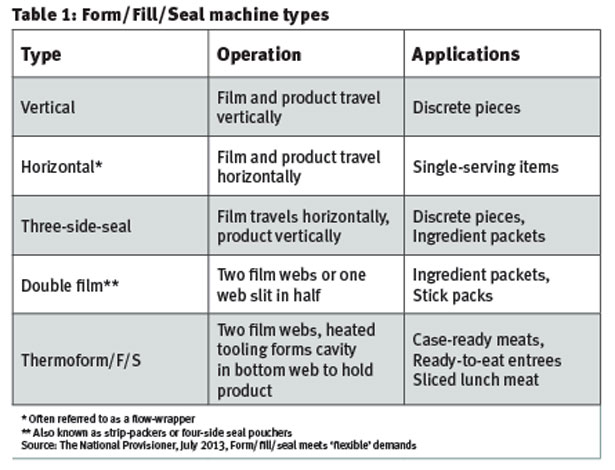

With several machine styles available (see Table 1), it’s essential to match current and anticipated needs to equipment features and to look beyond purchase price to total cost of ownership.

“Cost is always a factor,” notes Betsy Kusmierski, plant manager at Battistoni Italian Specialty Meats, a maker of dry sausage products in Buffalo, N.Y. Reliability was another criterion at the top of Battistoni’s thermoform-fill-seal wish list, so it selected a supplier with a stellar reputation in the industry.

“We also liked their ability to work with us to design something that perfectly fit our needs,” says Kusmierski, who explains the standard machine features custom, interchangeable die systems to accommodate different package shapes and sizes. In fact, the machine produces 6-ounce peel/reseal pillow packs, 1-pound packs, 2-pound saddle packs and 5-pound packs, and typically handles Battistoni’s sliced pepperoni, Genoa salami, hard salami or sandwich pepperoni.

The 6-ounce packs of sliced pepperoni are produced six-up and gas-flushed with nitrogen and carbon dioxide. An integrated thermal-transfer printer quickly adjusts to print smear-resistant product information in the correct spot(s) on the top web just prior to sealing.

Ease of integration also must be considered because FFS machines may connect with a variety of systems such as scales that deliver the appropriate weight of product for the package, coders/printers, checkweighers, vision inspection systems, metal detectors and vacuum/gas-flush systems. Machines also may integrate with upstream equipment or downstream cartoners, case packers and palletizers.

To simplify communication with other systems, many of today’s FFS machines have standardized on Ethernet/IP communication, and some rely on PackML (Packaging Machine Language) software. PackML standardizes terminology for machine states and streamlines machine-to-machine communication and data exchange, thereby simplifying line integration, operation and maintenance.

Other purchase criteria include the machine’s flexibility to accommodate product changes and downtime reduction. A flexible machine ensures a seamless transition to new products, package sizes/configurations and materials. Flexibility depends on modular design, networkability and easy programmability.

Important features include the ability to handle a variety of pack materials and features, accommodate retrofits such as the addition of a zipper applicator or switch from heat to ultrasonic sealing. Ultrasonic sealing minimizes product exposure to potentially damaging heat and produces good seals regardless of variations in material thickness or product contamination in the seal area.

Many of today’s FFS machines produce multiple pack styles such as pillow, gusseted and block-bottom bags. Size ranges can extend from about 2 by 3 inches to more than 18 by 23 inches. Output averages about 100 packs per minute.

Because productivity depends on maximum uptime, downtime must be as brief as possible. Fast setup and changeover, easy cleaning, high reliability, minimum maintenance and quick troubleshooting are essential.

Quick changeover minimizes or eliminates the need for tools and includes features such as hand cranks and scales and change part kits. Digital controls and servo motors and drives can automate all or part of the changeover process. Many of today’s machines store settings for each SKU in memory for recall at the touch of a button on the operator interface. Intuitive, icon-driven navigation on the operator interface, generally a color touchscreen, expedites setup, operation and diagnostics.

Hygienic design simplifies cleaning and minimizes downtime for cleaning. It involves stainless-steel construction and eliminates areas that could harbor product residue, dirt or moisture. Machines creating primary packages of meat, poultry and seafood withstand washdown conditions and meet sanitary standards set by organization such as USDA, 3-A and AMI.