Home » Keywords: » freezing

Items Tagged with 'freezing'

ARTICLES

Conference attendees can explore Air Products Freshline Smart Technology and food freezing solutions at booth 1074.

Read More

Commentary: AMSA

Freezing does not negatively affect the eating experience for consumers

Consumer panelists rate frozen samples as more tender than the fresh samples but found no other differences for juiciness or flavor.

Read More

Linde to display cryogenic gas technologies at Process Expo

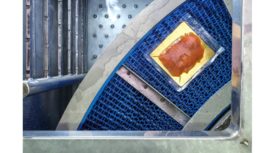

New offerings include a plate belt freezer, as well as a cryogen injection valve and system.

Read More

FPS Food Process Solutions opens new corporate headquarters as part of continued global expansion

FPS occupies the entire ground floor of the 23,000-square-foot facility.

Read More

Chilled to the bone

Carcass chilling temperatures affect meat tenderness, juiciness and taste.

Read More

Tech | Processing

Freezing and chilling technologies: Get sold on the cold

Leveraging the best freezing and chilling technologies can enable meat and poultry processors to enhance operations, but equipment capabilities must keep pace with expanding volumes for maximum benefit.

Read More

Processing Tech

Freezing, chilling become hot topics in meat and poultry processing

Processors that leverage advanced freezing and chilling systems are in position to boost the appeal of meat and poultry, but costs remain a concern.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing