Home » Keywords: » post-packaging pasteurization

Items Tagged with 'post-packaging pasteurization'

ARTICLES

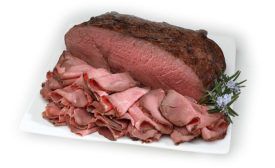

Providing another barrier for pathogens

Post-harvest pasteurization methods protect against foodborne pathogens, while keeping labels clean.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing