Home » Keywords: » conveyor systems

Items Tagged with 'conveyor systems '

ARTICLES

Overhead conveyor drives offer flexible input options, quiet

operation and industry-standard footprints.

Read More

Pacteon acquires Descon Integrated Conveyor Solutions

Pacteon reaffirms commitment to product-handling expertise.

Read More

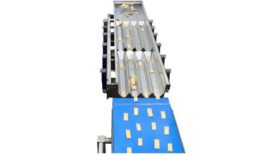

Key Technology introduces new conveying systems for robotic pick-and-place packaging

These systems are suitable for primary or secondary packaging.

Read More

Processing Technology

Conveyor cleanliness

Conveyors go a long way in enhancing worker welfare and reducing inefficiencies in meat and poultry plants, but they also are sources of potential food safety risks.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.png?height=168&t=1719304972&width=275)