ippexpo

When:

Jan. 30 - Feb. 1 2024

Where:

Georgia World Congress Center

285 Andrew Young International Blvd NW

Atlanta, Georgia USA

The International Production & Processing Expo (IPPE) returns to Atlanta for 2024 with its show floor expanded to include four halls - the event’s largest trade show floor ever. Attendees will discover the latest technology, equipment and services for the meat and poultry processing business – plus educational opportunities while connecting with protein industry professionals and supplier partners from across the globe.

2024 IPPE M2A Sponsors

Click on a sponsor logo to visit sponsor website.

News Feed

Exhibitor News

Show News

Expo Gallery

Sponsors

OSSID

Ossid is the industry leader for leak-resistant tray sealing for case-ready products, horizontal thermoform, fill and seal equipment, weigh/price labeling equipment, flow wrappers, vacuum chamber, and case scales. Catering to customers of all sizes around the world, Ossid’s packaging solutions are ideal for fresh and processed proteins. Ossid is a master distributor for Reepack, both are product brands of ProMach, a global leader in packaging line solutions. Ossid helps our packaging customers protect their reputation and grow the trust of their consumers. ProMach is performance, and the proof is in every package. Visit us in IPPE booth #C31129!

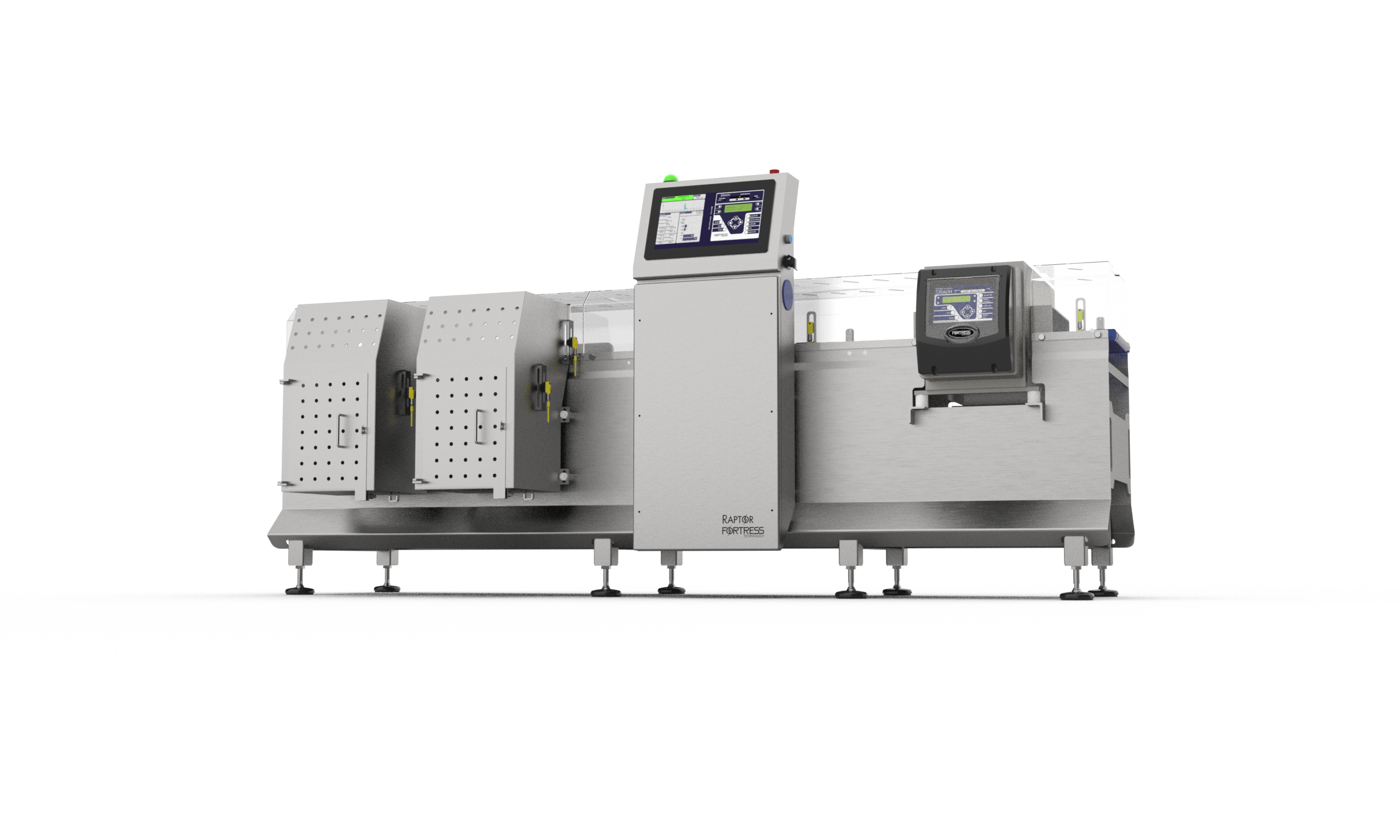

FORTRESS TECHNOLOGY

Enhance food safety and quality with Fortress Technology at IPPE 2024 in Atlanta, GA, from January 30th to February 1st! Join us at Booth C-019139, where we will showcase the latest innovations in metal detection and checkweighing technology tailored for the meat and poultry industry.

Discover how custom-designed inspection systems excel in detecting metal contaminants in piped products and large cases or bags. These systems are not only precise in safeguarding against metal contamination but are also essential in ensuring your products comply with weight regulations, reducing waste and preventing costly recalls.

Our focus at Fortress Technology is to protect consumers and support your business in maintaining the highest standards of product integrity and safety. Visit us to learn how our advanced technology can be an integral part of your processing line, enhancing both efficiency and compliance in a demanding industry.

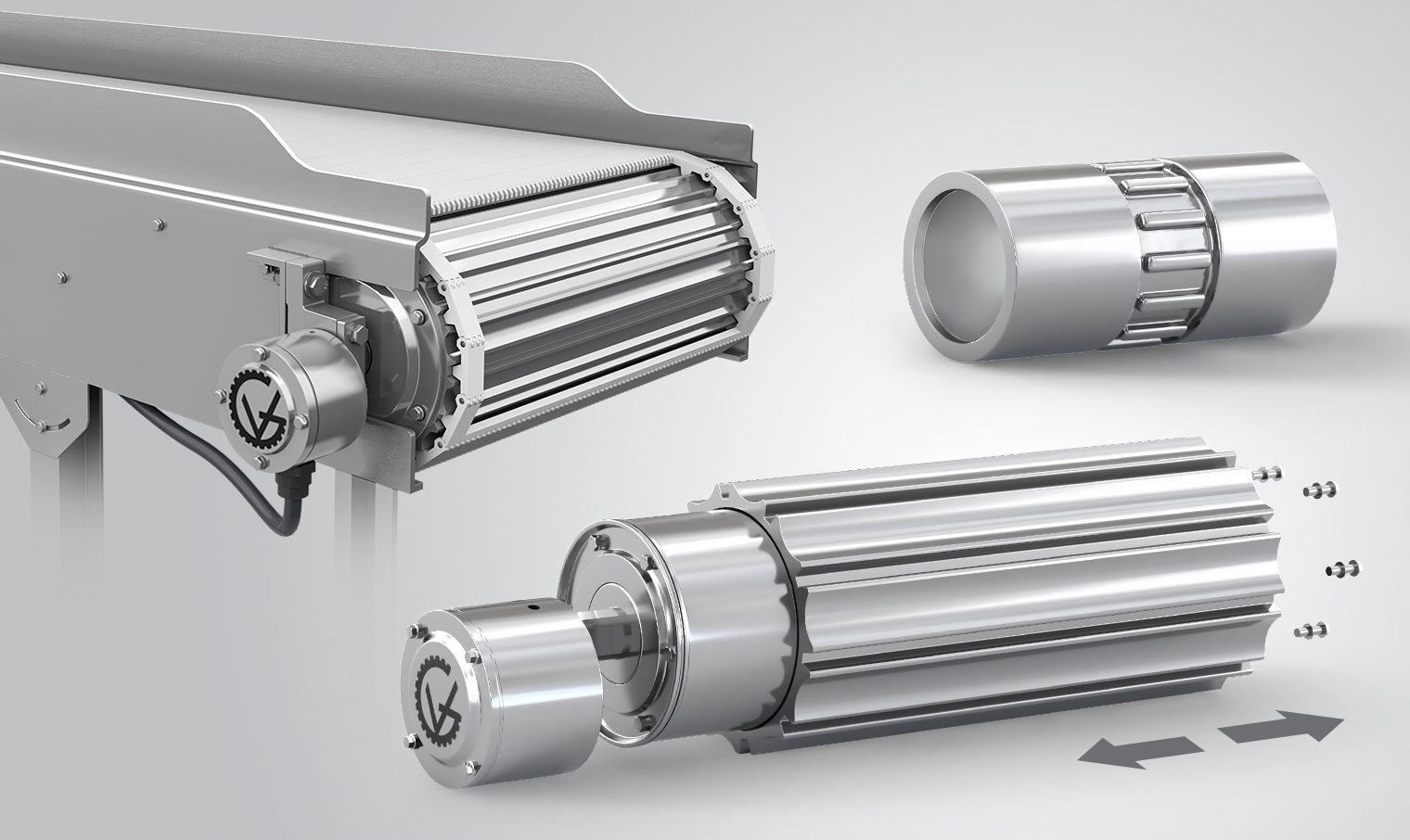

VDG (VAN DER GRAAF)

VDG is the leader in the design and manufacturing of drum motors for belt conveyors, with a strong focus on addressing safety, reliability, and longevity. Manufacturing in-house for 39 years in USA and Canada using cutting-edge production technology and automation, VDG ensures product quality, fast delivery, and after-sales support.

SSV Series Drum Motors are engineered for food processing and handling belt conveyor applications. With 80,000 hours of continuous operation before maintenance, an IP69K-rated sealing system and no external drive components, the SSV Drum Motor promotes operator safety, reduces operational costs, and increases throughput.

The new patented SSV-XP Drum Motor design has the belt profile machined directly onto the exchangeable profiled sleeve, offering processors the flexibility to use the same drum motor when switching to another belt for a different type of food processing. See the demonstration of the SSV-XP Drum Motor with the exchangeable profiled sleeve at IPPE Booth B40033.

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing