Articles by Lynn Knipe

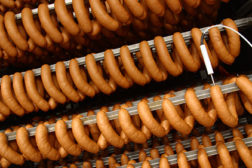

Cooking/chilling systems search for efficiency

Finding sustainable methods of operation and energy consumption rule the day when it comes to the challenges facing the cooking and chilling processes.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing