ARTICLES

Special Report

Barring a wild card, next year should yield moderate, increased production and stable prices.

Read More

Formulation Strategies

Dinner gets casual, creative

Consumers are looking for more creative dining formats and entrees at upscale casual restaurants, and at home.

Read More

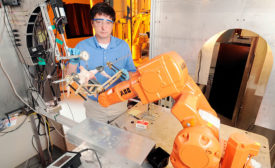

Cutting and deboning: Computerized butchers

Experiments with new cutting and deboning equipment aim to improve efficiencies, yields and worker safety.

Read More

Slicing technology: An innovative edge

Blade sharpeners, embedded chips and vision technology continue to keep slicers running.

Read More

Marinades, brines, spices get a Far Eastern influence

Exotic, spicy cuisines are directly influencing new marinades, brines and spices.

Read More

Providing another barrier for pathogens

Post-harvest pasteurization methods protect against foodborne pathogens, while keeping labels clean.

Read More

Special Report

Cooking & Chilling: A tale of two temperatures

Cooking and chilling systems are getting greener, faster and newer — yet still working together to keep product quality and safety at the top of its game.

Read More

Pre-harvest interventions beef up biosecurity

Pre-harvest interventions run the gamut of biosecurity, antimicrobials and carcass washes.

Read More

Formulation Strategies

Lunch Formulation Trends: 'Standard' out to lunch

As operators trim lunch menus, commodity offerings are losing out to options perceived healthier, more convenient, more sustainable and more unique in their flavor profiles.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing