Food Safety

Tech | Processing

Grease is the word

Meat and poultry processors that give high priority to lubrication can strengthen plant operations.

Read More

Tech | Processing

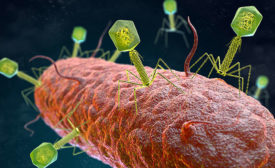

Battle versus bacteria heats up

Bacteriophages are providing more firepower for meat and poultry processors in the battle against microbials.

Read More

Commentary | Poultry Perspectives

Pest-repellent paint: poultry-safe, environmentally friendly

Read MoreProduct Focus | Metal Detection

Preventive maintenance for metal detectors

What it is and why it’s important.

Read More

Commentary | Regulations & Legislation

FSIS proposes to expand E. coli testing for non-O157 STEC

Read MoreStay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing