Food Safety

Tech | Supplier's Perspective

Electrostatic technology advances as antimicrobial intervention

Read MoreFight for Food Safety

Are food allergen advisory statements helpful?

'May contain' may not help

Read More

Tech | Food Safety

Designed Right: Automation and easy-to-clean equipment

Key components to sanitary design

Read More

Food Safety

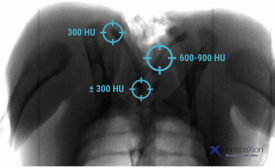

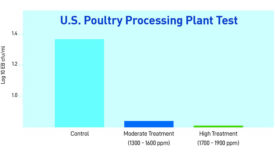

Improving effectiveness and efficiency of antimicrobial dips and sprays usage

Pushing the antimicrobial envelope

Read More

Food Safety

Rapid testing for pathogens in meat and poultry production

Need for (more) speed: Meat and poultry processors can generate greater yields while cutting protein waste by accelerating the testing for bacteria in production facilities.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing