Meat and Poultry Processing

Demand for cooked meat and poultry is on the upswing and preparation technologies are efficient, but generating mainstream acceptance of additional products remains a challenge.

Read More

Processing Technology

Forming technology shapes up

Technology is essential for developing high-quality protein products in specific sizes and shapes, but equipment is just one component necessary for success.

Read More

Meat Science Review

Can aging improve low-marbled beef?

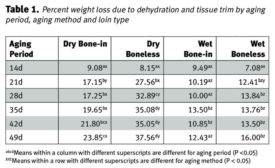

Effects of post-mortem aging time and type on palatability of low-marbled beef loins.

Read More

Food-grade lubricants: A slippery slope

Food-grade lubricants are becoming more effective, but users still face potential pitfalls.

Read More

Processing Technology

More meat, more problems

The move to larger carcasses may produce more protein, but it also complicates the processing and handling of whole-muscle cuts.

Read More

Meat Science Review

Helping meat science students communicate through challenges

American Meat Science Association’s 2016 Student Leadership Conference offers insights on being better industry communicators.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing