Meat and Poultry Processing

Processing Tech

De-stressing slaughter

Low-stress handling is key to humane slaughter and stunning practices.

Read More

Processing Tech

New take on protein processing technologies

Meat and poultry processors increasingly embrace plant automation to produce better quality products.

Read More

Processing Tech

Vision system technology advances food safety and quality assurance

A view of a safer future

Read More

Scaling down technological innovations for small sausage processors

Improvements in sausage production, such as co-extrusion, are becoming more affordable for more companies.

Read More

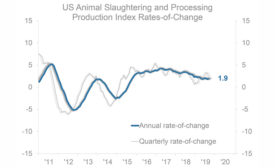

Market Snapshot | U.S. Animal Slaughter & Production

U.S. animal slaughter & production market: Pork flies ahead in processing marketplace

Read MoreProcessing Tech

The evolution of conveyors and belts in meat & poultry processing

In pursuit of a clean ride: Evolving designs are making it easier for meat and poultry processors to sanitize conveyors and belting, but food and worker safety risks remain.

Read More

Cover Story

FoodMaven sets out to minimize food waste in the supply chain

Food waste disruptor: FoodMaven has set out to minimize food waste in the supply chain by connecting out-of-spec and over-supply product with end users clamoring for cost-efficient raw materials.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing