Home » meat processing technology

Articles Tagged with ''meat processing technology''

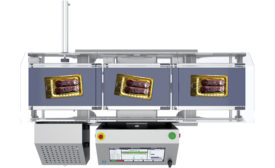

Operators providing meat and poultry to meet shoppers’ interest in portion control

Significant expansion opportunities await operators providing meat and poultry selections that meet shoppers’ growing interest in portion control.

Read More

Burgers’ Smokehouse: Enhancing the traditions

Burgers' Smokehouse embraces its time-tested curing methods while

modernizing and expanding its operations.

Read More

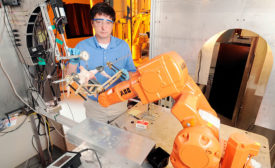

Cutting and deboning: Computerized butchers

Experiments with new cutting and deboning equipment aim to improve efficiencies, yields and worker safety.

Read More

Guest Commentary

The big 3 for R&D

Three areas on which meat-processing R&D teams should focus.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.png?1647275041)