Advertisement

NLB Corp.

Simplify Plant Cleaning, at a Lower Cost, with a Single High Performance Pump

Every meat processing plant operator knows that sanitation is critical. So are efficiency and cost-effectiveness. Connecting a plant’s cleaning and foaming systems to a single NLB hot water jetting unit instead of multiple pressure washers can deliver all three at the same time.

NLB’s rugged triplex pumps provide the pressure and flow needed to wash down production equipment or disassembled components, clean the IBCs used to hold liquid chemicals, and even clear clogged grates and drains. These are industrial units, designed for years of heavy-duty, high-volume use. They are built of iron and steel — with American-made components — to give users dependable, long-term performance with very little downtime.

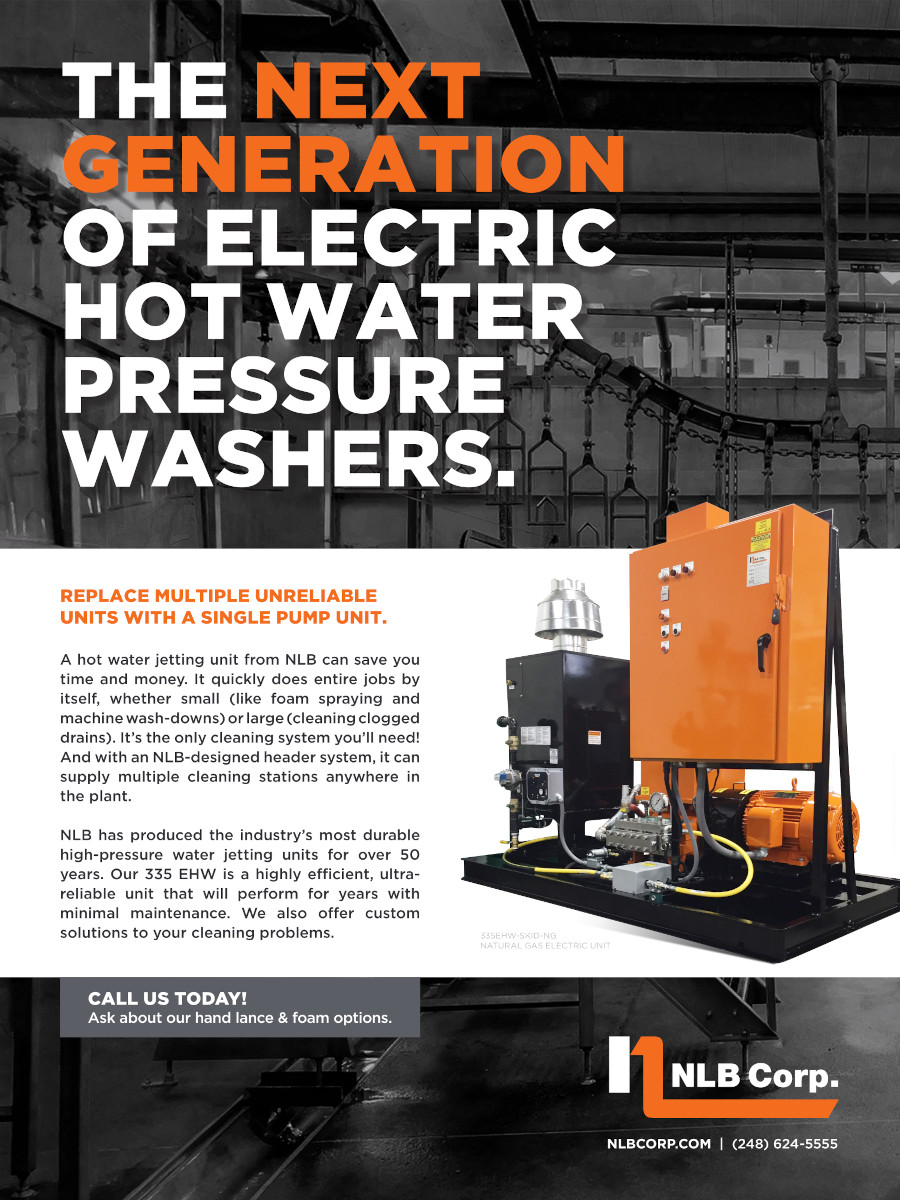

Diesel and electric units are available. The diesel-powered NLB 535 DHW-TRA-SA delivers flow of 9 gallons per minute at pressures up to 4,950 psi, and features a 420,000 BTU burner unit. It comes on a single-axle trailer (with a DOT-compliant frame) for mobility. The skid-mounted NLB 335 EHW-SKID-NG is electrically powered, and produces 15 gallons per minute of hot water at 3,500 psi. This high-efficiency, low-power unit has a 40 hp motor and a 700,000 BTU natural gas burner.

Both models have features not typically found in hot water units, such as integrated water lubrication lines and a 75-micron inlet strainer (instead of the traditional filter) that can be rinsed and reused. The rupture disk, a common replacement part, has been replaced by a self-resetting pop-off valve.

Either unit can easily be connected to a header system via a drop-down hook-up, to provide hot water wherever it’s needed without running hoses all over the floor. Experienced NLB engineers can design a header system to meet a plant’s unique requirements. Replacing multiple pressure washers with a single hot water unit from NLB helps meat processors improve cleaning efficiency with less downtime and maintenance. This lets them maintain their high levels of sanitation at a lower operating cost.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!