Tech | Processing

Ousting foreign objects is no. 1 in meat and poultry plants

The ample opportunities for foreign object contamination in meat and poultry plants makes prevention a top priority for protein processors.

Meat and poultry plants are a conglomeration of perpetually moving parts.

The incessant activity in processing facilities of machinery, workers and production lines, combined with the development of myriad products from thousands of pounds of raw materials, makes the environments ripe for food safety perils, and especially contamination from foreign objects.

Indeed, the threat of such elements as metal, bone, hard plastics, rubber, wood, glass and stone infecting proteins makes it essential that processors develop and enforce adherence to strict safety protocols both within their plants and by suppliers, analysts note.

“Any object that is hazardous to a consumer is the greatest food safety risk,” says Jonathan Campbell, extension meat specialist and assistant professor, animal science, in the Department of Animal Science at Penn State University in University Park. “Risk may not have to do with material type as much as size, particularly if it could be a choking hazard.”

Many foreign objects are potentially hazardous as the materials also can “cut, irritate or even puncture the gut lining and digestive track of consumers if swallowed,” he states.

Metal contaminants pose perhaps the greatest safety threat because of the prevalence of the material in plant machinery and hand-held tools, yet a plethora of other possible dangers also are common in facilities. That includes seemingly insignificant smaller articles that can potentially end up in products, including pens, pencils, clips, tags and rubber washers, analysts note.

“The greatest foreign object hazards are those that have the capacity to cause human injuries if ingested,” says Davey Griffin, professor and extension meat specialist in the Department of Animal Science at Texas A&M University in College Station. “Metal and glass are most obvious, but anything rigid and sharp also may cause injury. There are many materials that operators must consider and guard against.”

Among the most prominent articles are the plastic or rubber gloves that workers wear to enhance food safety during production, he notes.

Employees, for instance, can nick off the end of a glove when trimming meat, or put the gloves in a vulnerable spot at the end of their shifts, Griffin says.

“If workers get complacent, the gloves can show up in a combo bin and accidently get ground up with the raw meat,” he states.

Prevention = priority

As a deterrent, plant workers can wear gloves that are orange, blue or another odd color to make the materials easier to visually locate in meat and remove before packaging, Griffin says.

Visual inspections for contaminants, particularly in incoming raw materials, is the “first line of defense” in most facilities, he states, noting that workers who notice hard plastic and any other larger materials in combo bins during the early stages of production can prevent both food safety incidents and possible damage to the processing equipment.

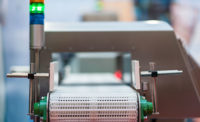

Operators typically leverage metal detectors and other scanning technologies during the latter stages of production and on finished products, Griffin says.

Metal detectors can identify small levels of contaminants in ground meats and other non-solid muscle products, particularly after the raw materials move through a grinder, he states, adding that plants often use X-ray systems to identify bone fragments and other elements.

“Processors aren’t going to catch tiny pieces of metal with visual inspections,” he states. “But visual examinations will often locate larger hazards,” including gloves, hand-held equipment, meat hooks, knives and additional objects that have fallen into bins before the raw meat reaches processing plants.

“Objects are obviously more difficult to see once they get into the grinder so metal detectors are necessary for that second step,” Griffin notes.

Hazards can originate from almost any piece of machinery or instrument in processing facilities, with worn equipment that produces slivers of metal and other particles perhaps the most frequent sources of contaminants, he states. Such machinery can include grinders, mixes, slices, dicers and conveyors, analysts note.

For prevention, processors should routinely examine equipment, which could be as frequent as hourly, to pinpoint potential hazards that need attention, Griffin notes.

More extensive equipment inspections can occur during the daily sanitizing when workers who disassemble machinery for cleaning may more easily check for such elements as cracks, wear and the loose materials that result from constant metal on metal, metal on plastic and metal on rubber contact, says Lynvel Johnson, an associate with HACCP Consulting Group Inc., an Alexandria, Va.-based food safety and HACCP consulting and training firm.

Maintenance workers, meanwhile, can focus on preventative measures, which includes routinely replacing parts before there are signs of damage, he says.

Ground meat and poultry are most likely to have contaminants, Johnson notes, stating that it is relatively rare to find foreign objects within solid muscle cuts as such materials would typically be on the outside of a product or in a bag and are simpler to spot and remove.

Reduce supply risk

While many potential contaminants originate in meat and poultry processing facilities, suppliers that ship raw materials to plants, often in large combo bins containing 1,500 pounds of product, also can be sources of hazardous objects, Johnson states.

Indeed, he notes that while operators rely on their suppliers to remove bones and other potential hazards, mishaps still arise. Processors can help reduce occurrences by establishing security guidelines for their vendors and conducting audits to ensure there is compliance, he says.

“Audits are an area that can be lacking at times,” Johnson says. “Processors want to ensure there are controls and specifications in place and that suppliers are complying.”

The high worker turnover rates in meat and poultry facilities, meanwhile, is creating inexperienced workforces and making it more challenging for processors to prevent incidents, Griffin says.

It is imperative that new hires receive proper food safety training, and for operators to ensure that all personnel keep foreign material detection top of mind, he notes.

Problems occur when workers, who are primarily focusing on product yield and quality, become complacent and neglect to regularly inspect machinery for hazards or adequately monitor the whereabouts of all tools and supplies in work spaces, Griffin states.

“It is human nature to get complacent over time and assume the situation is like it was the day before,” he notes. “But because every day is an opportunity for new incidents to occur, it is vital for workers to remain vigilant.”

Operators, Griffin says, need to continually remind employees about potential food safety hazards and the importance of enhancing consumer confidence in products. Methods can include posting letters with shopper complaints about foreign object incidents or displaying signs that tout the facility’s safety record, he states.

Because a large amount of plant workers are typically foreign born, it also is essential that processors devise systems to effectively communicate with all employees, Campbell says.

“Many different languages are spoken in food processing facilities and there may be a wide variety of literacy among workers,” he states. “This can make retention and comprehension of information very challenging.”

In addition, processors need to routinely train employees to follow both the company’s good manufacturing practices (GMP) that meet the U.S. Food and Drug Administration’s regulations for product quality, and its standard operating procedures that are intended to ensure that workers are addressing all potential hazards, Campbell says.

Among such measures, for instance, may be rules that prohibit the removal of gloves and the use of food containers and glass bottles in production areas, or procedures that govern the use of wood pallets that hold combo bins to ensure that pieces of wood, as well as nails and screws, do not fall into grinders when processors hoist the pallets during processing, Johnson notes.

Operators, Griffin adds, have “pretty much eliminated anything glass in most meat plants to be sure it does not become a contaminant.”

Keep track of tools

Documenting all the items that workers use during production or that persons bring into facilities, including smaller tools, tags, pins and writing instruments, and insuring that the materials are all accounted for at the end of the day, also is critical for minimizing food safety threats, Johnson notes.

“Having check-in and check-out procedures to verify that operators are getting the right number of knives and other objects back is critical,” he states. “It is important to have control over materials to make sure they are not getting lost.”

Indeed, Betsy Kaesontae, manager of managed services North America for NSF International, an Ann Arbor, Mich.-based certification organization that does supply chain assurance and second- and third-party auditing for food manufacturing and processing companies, says that a lack of check-in and check-out for maintenance tools and knives is a common operator mistake.

She states that metal and sharp plastic objects pose the greatest food safety risks during meat and poultry production and that X-ray machines will have the most significant impact in reducing or eliminating such dangers.

The relatively high price of the technologies, however, which can often cost in the five figures, makes the equipment cost-prohibitive for many processors, and especially smaller operators, Griffin says.

“Some smaller processors benefit by buying raw materials from the larger plants that have more extensive detection machinery,” he states. “But the key is to still focus on eliminating potential problems within plants.”

Due diligence on detectors

Operators considering the use of X-ray technologies should perform a cost/benefit analysis, Johnson notes, which includes weighing the chance that plastics, bones, rubber and other materials will contaminate products.

He states, meanwhile, that it frequently is inadvisable for the smaller processors that are more “hands-on” and use little automation to invest in X-ray systems.

The more likely candidates, Johnson says, are plants that produce products with multiple ingredients, including such agricultural items as vegetables along with meat and poultry, and face greater foreign object risks. “They will have X-ray systems because of the higher probability of non-metal contaminants getting into products, including rocks,” he states.

The performance levels of both X-ray and metal detection devices, meanwhile, are constantly improving and “have come a long way” in helping to prevent foreign object contamination in meat and poultry, Johnson says.

He notes that newer safety technologies also are becoming more prevalent. Those include meat and bone separating machinery and equipment that is able to detect and remove unwanted materials in accordance with type, density or other parameters during processing without causing major yield losses, Johnson says.

Indeed, Campbell states that it is vital that processors “stay on top of applicable technologies, implement best practices and invest in food safety as a cost of doing business. Most importantly, provide the education so employees understand the huge role they play in preventing incidents or how they can potentially add to the hazards that can occur during food processing.”

That is important as the numerous steps and touchpoints inherent to meat and poultry processing will make the threat of hazardous incidents omnipresent, Kaesontae indicates.

The range of such activities in which contamination can occur, she notes, includes slaughterhouses shipping products to processing plants, and the proteins going through aging, trimming, cutting and packing processes.

Operators, she agrees, can best safeguard meat and poultry by conducting audits of the procedures to ensure that both processors and their suppliers are following stringent food safety practices.

“Processors are more vigilant than ever, but things are still going to slip through the cracks,” Griffin adds. NP

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!