Food Safety

Improving effectiveness and efficiency of antimicrobial dips and sprays usage

Pushing the antimicrobial envelope

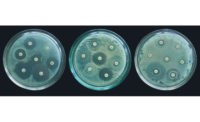

Antimicrobial dips and sprays are aiding processors in achieving food-safety goals from animal harvest all the way through various points of processing, including fresh-cut products. By using antimicrobial dips and sprays, pathogens such as Salmonella, Listeria monocytogenes and Campylobacter jejuni along with Shiga toxin-producing Escherichia coli, can be reduced in numbers on carcasses as well as reduced in frequency of carcasses that bear pathogens.

“Bringing pathogenic bacteria to zero without having a very specific process such as cooking, radiation or pasteurization is often not achievable, so the goal is always to reduce to levels that are as close to zero as possible realizing that completely eliminating bacteria on the raw side without a more invasive method, which can have a detriment of quality, is not realistic,” explains Jeff Sindelar, extension meat specialist at the University of Wisconsin-Madison. “Dips and sprays aid in a food-safety systems with proper hygiene process, sanitary design of equipment, good manufacturing practices, well developed and effective standard operating procedures as well as sanitation standard operating procedures. All of that goes into aiding in a system, and then all of that allows the antimicrobial dips and sprays to be even more effective.”

While the meat industry widely uses organic acids such as lactic acid and the poultry industry traditionally uses peracetic acid, much research and development is occurring with new antimicrobial dips and sprays to further aid in food-safety, conservation and clean-label endeavors. For example, at least a few new antimicrobial dips and sprays are approved quarterly by the U.S. Department of Agriculture Food Safety and Inspection Service (FSIS).

“The red-meat industry, particularly the beef industry, has really done a lot to support and encourage research looking into other types of antimicrobial agents,” says Matthew Taylor, associate professor in the Department of Animal Science at Texas A&M University, in College Station. “And so now if you were to look at the FSIS’s listing of approved antimicrobials, it’s grown extensively in the last 10 to 25 years, and in large part that’s been because of the meat industry.”

In the past decade, several new antimicrobials technologies have been developed that are based on the use of bacteriophages, viruses that are obligate predators to bacteria. Phages themselves are not a new technology and have disadvantages, including being organism-specific and being in direct contact with the pathogen for effectiveness. Phage technological developments continue, though, and Taylor expects the industry will see phage products developed that could also eliminate very significant spoilage organisms.

In addition to new antimicrobial dips and sprays, reformulated antimicrobials and new combinations of antimicrobials are other areas where much development is occurring, Taylor says.

With the different antimicrobial dips and spray options, processors now have more ability to fine-tune antimicrobial usage with their products, in their processes and for certain pathogens, Sindelar adds. An opportunity also exists to include a multihurdle approach in which processors can have combinations of different active antimicrobial ingredients that together can be more effective than any one alone.

While historically the industry has used a small number of antimicrobial dips and sprays, research and industry knowledge has allowed processors to better understand which factors make antimicrobials most effective. Everything related to the makeup concentration of these antimicrobial dips and sprays, including temperature and concentration, along with the method of delivery as well as the attributes of that delivery, such as spray pattern to pressure to surface conditions of the product in which the application was occurring along with exposure time, all are factors in effectiveness, Sindelar says.

Taylor agrees that processors have an opportunity to partner with suppliers and scientists to explore process design options in terms of antimicrobial application.

“Do you engage in a hurdle process where you might apply multiple antimicrobials in a specific sequence?” Taylor asks. “Do you apply antimicrobials in combination with other types of processing measures? There still is an opportunity to really improve upon that as it were.”

The clean-label movement also has pushed the industry to look at new sources of antimicrobials dips and sprays. For example, research into replacing traditional synthetic compounds with natural alternatives is happening. Many in the industry rely on hot water as well for bacteria reduction.

Another area of research and development is the conservation of resources while growing efficiencies, Taylor says. In the case of antimicrobial dips and sprays, this translates into using less water and energy. In recent years, new technologies have emerged from antimicrobial dips and spray suppliers, who might not only supply the chemistry but also the machinery that captures, recycles and thermally pasteurizes the water that drips off post antimicrobial dip and spray application. The water is then fed back through the system again, reducing water usage.

“Every company needs to be thinking about how can I upgrade the efficiency of my process to use less antimicrobial, use less water, use less heat, use less power, use less whatever so that I can conserve those resources better, but at the same time, that I’m still able to meet my production needs,” Taylor says.

Taylor’s research at Texas A&M focuses on how processors can upgrade the efficiency of their process to use fewer antimicrobials through the use of encapsulation. He is working with natural antimicrobials derived from various plant sources that presently don’t have a lot of utility in meat and poultry because they tend to put a lot of compound into the formulation of the meat product to get any functional antimicrobial activity. Taylor’s lab is building encapsulates that essentially help protect the antimicrobial up until the point of processing or up until the point they contact the pathogen.

Taylor’s research team is working to build systems that can be useful in deactivating Listeria monocytogenes or Salmonella on products such as a hot dog, sausage or deli roll where the encapsulate works to essentially protect the compound up until the point it is needed for contacting the pathogen. While formulating antimicrobial encapsulate technology for meat and poultry products that eventually get cooked is very complex, Taylor believes the opportunity exists to push the envelope of formulating new encapsulating technology to improve upon antimicrobial activity for protecting food safety and even against microbial spoilage. NP

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!