Food Safety

Pasteurization options continue to grow

For pasteurizing product, processors have a variety of options on the rise, but thermal processing remains entrenched as the proven option for many companies.

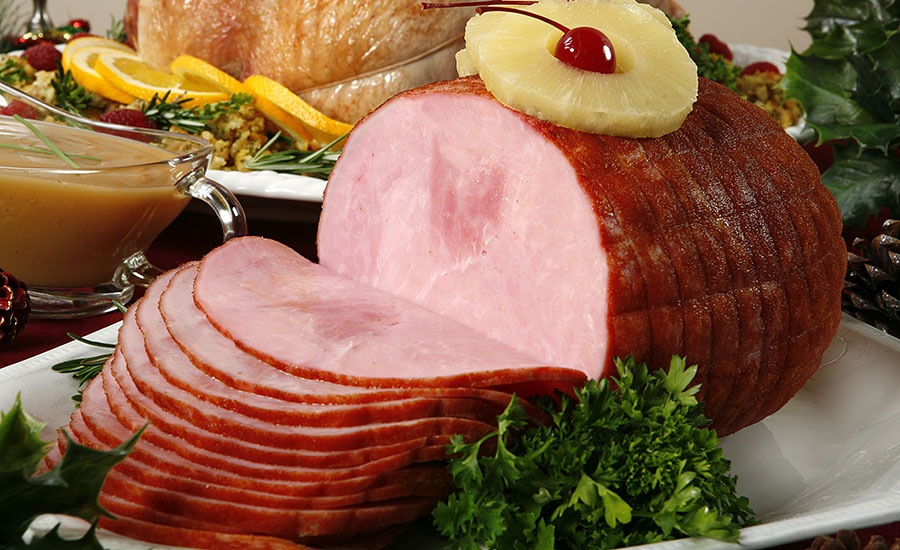

Thermal processing is a proven option for post-packaging pasteurization.

Thermal processing uses heat to kill bacteria, while HPP is a cold pasteurization technique.

In the world of post-packaging pasteurization, change is more a concept than a reality — for now.

Although a slew of systems, including lighting technologies and the use of radiation, are taking shape and likely to become more active or launch in the coming years, thermal processing still is the dominant pasteurization method for enhancing food safety in meat and poultry, and it will be difficult to displace in the short term.

Because it has a long head start as a viable post-packaging pasteurization system and costs less to implement than high-pressure processing (HPP), the primary replacement option, thermal processing remains entrenched, says Larry Keener, president and chief executive officer of International Product Safety Consultants LLC, a Seattle-based validator of food safety technologies.

“We have been using thermal processing for more than 100 years, and it has been shown to be a safe and efficient way to pasteurize food products,” he says. “It is very effective in killing bacteria and the meat and poultry industry has a great deal of experience with it.”

Because many protein processors have large investments in thermal post-packaging pasteurization technologies, Keener says it will take a major change in the system’s effectiveness or economics before most would switch to HPP or other options.

“There is a high entry fee to obtain any new technology, but once it becomes popular and sales increase, the prices tend to comes down,” Keener says.

The cost component

Thermal processing uses heat to kill bacteria, while HPP is a cold pasteurization technique, in which products are immersed in water and receive a high level of isostatic pressure.

Because HPP expenses typically are about 3 to 5 cents per pound more than thermal pasteurization, the steeper operational costs will keep many potential users at bay, says V.M. (Bala) Balasubramaniam, a professor in the departments of Food Science and Technology, and Food Agricultural and Biological Engineering at The Ohio State University in Columbus.

“Thermal processing goes back more than a century so it is much more affordable,” he says. “More processors are using it so equipment manufacturers can mass produce the technologies at a lesser cost. It is more expensive to create limited supplies of newer equipment.”

Much of the HPP activity in the industry is occurring with toll processors — service providers who contract with meat and poultry processors to handle their HPP business.

Balasubramaniam notes operators can offer an economical outlet for small or medium-size protein processors whose volumes are too sparse to justify the expense of purchasing equipment. Costs, however, can be relatively steep when using toll processors because of the need for the operators to cover their overhead expenses, Balasubramaniam says.

Such costs also can differ in conjunction with the additional services that meat and poultry processors use, says Amy Lawless, managing director of Stay Fresh Foods LLC, a Meriden, Conn.-based HPP toll processor. Options, for instance, can include having the service provider box and ship proteins to retailers from their facilities in lieu of sending the items back to the production plant following high-pressure processing.

In addition to HPP, lighting systems — particularly ultraviolet applications — also could threaten the use of thermal pasteurization technologies, says Tatiana Koutchma, research scientist in novel food technologies for Agriculture and Agri-Food Canada in Guelph.

“There are many challenges in commercializing newer technologies,” she says. “The cost of high-pressure processing is quite high compared to thermal processing. While ultraviolet lighting is less expensive, there are not many commercial units available. Yet it has promise because of the expense, convenience and effectiveness against all types of spores and microorganisms.”

She says an ultraviolet unit can cost approximately $20,000 to $50,000 and that equipment costs are likely decrease over the next few years as ultraviolet evolves from using mercury low-pressure lighting to less expensive light-emitting diode (LED).

Yet, though such replacement systems are set to emerge and further evolve, thermal processing with remain the key post-packaging pasteurization method for at least the next five to 10 years because of its widespread use, the greater availability of units and an appealing cost, Keener says.

Nevertheless, he says thermal systems also will undergo transformations.

Likely to become prominent is pressure assisted thermal sterilization (PATS) technology, which uses a combination of pressure and temperature to more quickly pasteurize proteins The process can help stem the degradation of meat and poultry that can occur during traditional thermal processing, Balasubramaniam says.

While proteins undergoing PATS are heated to a similar temperature as that for common thermal processing — about 240 to 250 degrees Fahrenheit — the cycle time is approximately 12 minutes compared with about 70 minutes for thermal processing, Keener says.

“There is a big improvement in food quality and the nutrition profile when the meat has not been beat up so much by heat and overcooking,” Keener says. “Product color and flavor also are more appealing.”

Another thermal process with potential is pressure-enhanced sterilization (PES), which uses extreme pressure for three minutes to kill bacteria at more moderate temperatures, he adds.

“The technology exists for pressure-enhanced sterilization, but it is up to the equipment suppliers to build commercial-grade units for the process,” Keener says.

While he notes there will be opportunities for the use of both PES and PATS systems, which have so far primarily just been active in pilot programs, issues still must be overcome for widespread acceptance.

Processors, for instance, must take the time-consuming step of preheating products for 10 to 12 minutes before the thermal and compression treatments, he says.

“Developers of pressure enhanced sterilization and pressure assisted thermal sterilization will be trying to displace retort processing and the thermal pasteurization currently in use, but that is a big challenge because processors are already heavily capitalized with traditional thermal processing equipment,” Keener says. “To change their technology will be a very big step. The main question is whether PATS and PES are a large enough game-changers.”

He says that while some operators will have a chance “to create new, better and more innovative products using PATS and PES,” it will be difficult for many to eschew the investments in their current technologies.

Also making it harder for PATS and PES to take hold will be the greater acceptance of other competing technologies, including radiation and microwave systems, Balasubramaniam says.

“Microwaving an entire mass of protein at once will help reduce product degradation,” he says. “Radiation also is an effective technology for pasteurizing meat products, but a lack of consumer acceptance is keeping it from generating traction in the industry, but that could eventually change.”

While she agrees radiation remains unpopular because of safety concerns, Koutchma says the emergence of equipment with low-dose electron beams could likely make the technology more acceptable to consumers.

Though such options may eventually become more prominent, thermal processing and high-pressure processing will remain the dominant post-packaging pasteurization technologies for the foreseeable future, Keenan says, with HPP apparently in position to undergo rapid growth. NP

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!