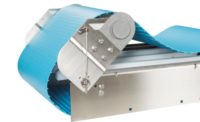

Multi-Conveyor recently provided a single stainless steel constructed, pneumatic controlled sanitary quick release tool-less belt conveyor for transporting temperature controlled raw meat product at a volume of more than 50,000 lbs per hour.

The conveyor has a retractable idle and drive end with a center take-up. The retractable idle end operates with a customer supplied metal detector to reject product at the infeed. The retractable drive end operates in two positions to dispense into either of two hoppers positioned at the discharge.

A check weigher triggers the divert to move from one side or the other based on weight for continuous processing. While a manually adjustable belt scraper w/catch pan scrapes off excess product that does not fall into the totes.

Sanitary specifications included a mill finish with electro-polish. All welds had to be continuous, free of pits, cracks and crevices. The retractable "noser" frame itself is completely removable. The controls are located in an offset sanitary enclosure.

Electrical components are mounted in a single NEMA 4X stainless steel slope top enclosure which houses a through-door disconnect, an Allen Bradley PowerFlex® 40 AC motor controller, Safety Relay, Micro Logix PLC, extend and retract actuators and other control devices.

This conveyor runs up to 60 FPM @ 60 hertz based on a product load of nearly 20 pounds of product per lineal foot of conveyor in a distributed load with no accumulation.

For more information, call toll-free 1-800-236-7960, email at info@multi-conveyor.com or visit www.multi-conveyor.com.