New AirTrim MITS-AIO/2-MX allows Portable Pneumatic PSA Matrix Collection an economical way to automate matrix removal on PSA Label Press

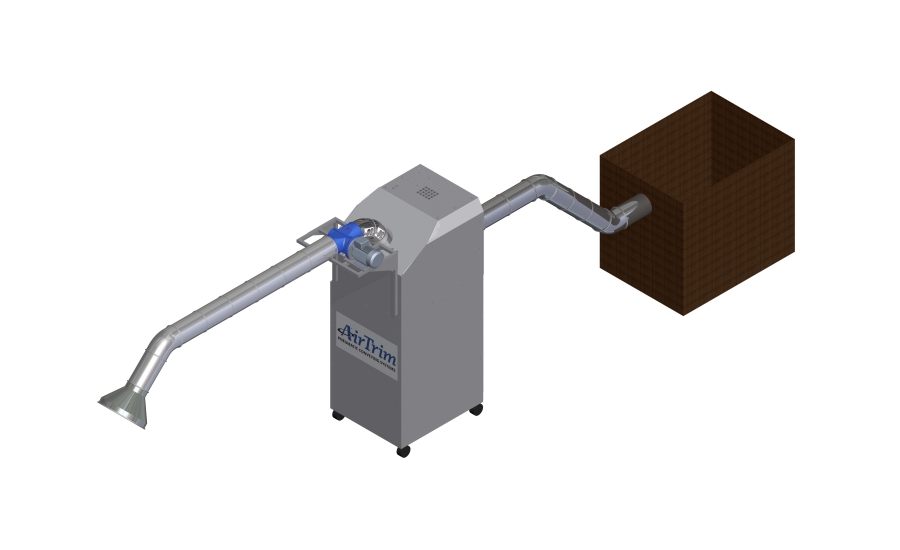

AirTrim introduces the new MITS-AIO/2- MX portable trim collection unit to chop and collect PSA matrix and edge trim from PSA label presses. The newest offering in the “Move It Trim System” includes control, trim intakes, duct, fan, silencers, cutter, and dust filter all housed in an attractive powder coated steel cabinet. The air/material separator is a separate unit to allow the most flexibility for location and sizing considerations. Shredded output is fed through ductwork to a collection hopper. This highly portable and economical “MITS-AIO-MX/2” unit built around a proven Lundberg Tech™ cutter technology is designed specifically to cut the most aggressive adhesive found on label matrix. In addition to allowing presses to operate more hours per week, the MITS-AIO/2-MX also can allow faster press speeds, and potentially reduces raw material costs.

“This is ideal for smaller PSA label manufacturers that desire more production efficiency but often lack the funding resources for larger, central systems,” said AirTrim President Robert Patton. “This portable technology improves production efficiencies on specific presses, at very competitive prices. Flexible rental options are available to prove the technology on-site and eliminate risk.”

The popular practice of rolling up matrix on an air shaft incurs a significant long term cost—it requires stopping the press for each matrix removal application. This causes PSA label manufacturers to lose valuable production time, repeatedly. In addition, traditional pneumatic rolled matrix often requires the press to operate at slower than designed speeds to insure weaker matrix remains intact. Finally, depending on the matrix fragility, PSA label manufacturers often need to purchase wider than needed web stock just to increase the strength of the matrix. Virtually all of those considerations are addressed with the MITS-AIO/2-MX, which includes all of the components found in larger systems for high efficiency matrix removal, but in a compact size that fits most tight spaces.

Weighing approximately 500 pounds and mounted on heavy duty lockable casters, the compact design allows operators to move unit easily from one machine to another, wherever needed within the facility. These durable and portable units are suitable for voltages of 208/240/480V at 60Hz; UL-certification is optional.

Movable pneumatic matrix removal systems generate significant payback, often less than 12 months. Portable units benefit specific production applications, improving productivity to reduce per-piece costs manufactured on those lines. Driving down per-piece costs allow users to realize more competitive pricing and pass that along to customers, and generate higher cash flow. MITS products typically ship within 2-3 weeks, depending upon model and options selected.

AirTrim is a leader in designing, building and installing pneumatic material handling systems for domestic and international customers. From its centrally located Springfield, OH headquarters, they develop systems for a wide range of industries, including converting, food processing, fulfillment (digital printing), labelling, non-wovens and textiles, paper and tissue mills, printing, packaging, pharmaceutical and medical, plastics, recycling, and more. They evaluate each application individually to provide transmission and containment ideally suited for that particular situation. For additional information visit www.airtrim.com, email to sales@airtrim.com, or call (888) 247-8746.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!