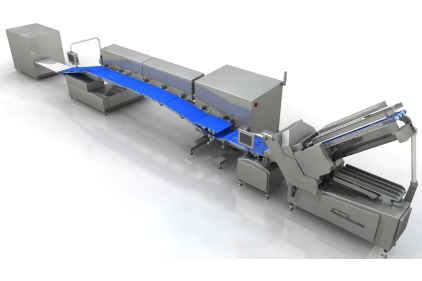

Multitec Autoloading Systems offer the most slice positioning capabilities in the industry

A growing number of value-added meat and poultry processors must satisfy a staggering array of divergent product needs on a shift-by-shift basis. Forward-thinking food product manufacturers are discovering they can bank most on Multitec Autoloading Systems to provide them with the crucial link they need between their Formax Slicing/PowerMax and packaging equipment. Both brands are members of the Provisur Technologies Inc. family of processing solutions and offer many unique features.

A growing number of value-added meat and poultry processors must satisfy a staggering array of divergent product needs on a shift-by-shift basis. Forward-thinking food product manufacturers are discovering they can bank most on Multitec Autoloading Systems to provide them with the crucial link they need between their Formax Slicing/PowerMax and packaging equipment. Both brands are members of the Provisur Technologies Inc. family of processing solutions and offer many unique features.

Formax’s PowerMax slicing systems feature an open, hygienic design to ensure enhanced food safety due to the systems’ ease of effective cleaning and sanitation. And the slicing throat, which is up to 18.5 inches (470mm) wide, assures greater throughput to maximize productivity and yields.

Meanwhile, Multitec’s patented technology ranges from the most basic of autoloading needs up to the most complex of applications. Incorporating Multitec Autoloading Systems’ patented technology allows processors to automate the positioning, transfer, and loading of their sliced portions at high speeds– which rewards them with optimum efficiency and more throughput.

Belt-loading systems included in Multitec technology fully support product portions throughout the transfer and loading process ensuring consistent performance. Multitec Autoloading Systems makes the final correction to each row alignment just prior to packager to ensure product placement is both consistent and precise. You can overlap adjacent portion lanes or subsequent rows onto one another with overlapping systems to create variety packs, sandwich setups, and other portion presentations. With Multitec’s innovative design, this can be accomplished in a very small footprint.

Positioning Station high-speed camera technology detects and adjusts portion position to meet the application requirements. Modules drag, turn, and line the portions as required, which is ideal for high-speed cheese and deli meat packaging. Inliner and Twinliner Stations streamline multiple lanes of portions into a single lane for packaging or split single lanes into separate ones. Throughput capacity can reach 100 portions per minute for the standard model or 150 portions per minute maximum for the high-speed model.

By using proven modular designs, Multitec Autoloading systems can be designed for unique application needs. Multitec offers the most slice positioning capabilities in the industry. Almost any product presentation can be loaded into any packaging format. Robotic loaders are also available depending on the application.

“Combining Formax Slicing technologies and Multitec Autoloading solutions gives you more power, better flexibility, increased throughput, improved product presentation, and enhanced food safety,” said Brian Sandberg, Global Product Manager, Slicing and Autoloading, for Chicago, Ill.-based Provisur® Technologies.

See how you can improve your line performance. Go to www.FormaxMultitec.comto watch the exclusive Video and read the White Paper. For immediate assistance call Brian Sandberg, Global Product Manager, Slicing and Autoloading at (708) 479-3650.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!