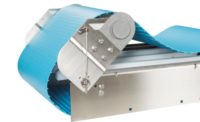

Snake up and down, in and out of equipment with Dorner’s new AquaGard 7100 Series Table Top Chain Conveyor

Dorner’s new AquaGard 7100 Series Stainless Steel Table Top Chain Conveyor can twist and turn into the tightest of spaces. The flexibility is ideal for product routing in wipe down sanitary applications in the food, packaging and pharmaceutical industries.

Dorner’s new AquaGard 7100 Series Stainless Steel Table Top Chain Conveyor can twist and turn into the tightest of spaces. The flexibility is ideal for product routing in wipe down sanitary applications in the food, packaging and pharmaceutical industries.

As the footprint around machinery, production areas and plants continues to shrink, the AquaGard 7100 Series Stainless Steel Table Top Chain Conveyor is the ideal platform to maximize available space. The conveyor is engineered to make tight turns, and be configured for inclines and declines to provide the ultimate in flexibility for customers. The innovative design includes powered micro pitch transfer modules and side transfer modules for maximum performance. The sleek frame design includes the latest technology and components for unmatched performance and durability. And with the sanitary attributes of the AquaGard platform - the 7100 Series delivers a great solution.

The AquaGard family of sanitary conveyors is a stainless steel line that offers maximum flexibility for a wide variety of products and applications, while increasing throughput and reducing product loss.

Features and benefits of the AquaGard 7100 Series Stainless Steel Table Top Chain Conveyor include:

- Sleek frame design with long conveyor runs

- Fast belt speeds up to 250 feet per minute

- Superior product transfers

- 300 Series stainless steel

- FDA approved plastics and stainless steel

- Chain widths: 4 1/2", 7 1/2", 10” & 12”

- 600 pound load capacity

- Plain bend corners with 24” on centerline radius

- Wheel bend corners available on 4 1/2" width radius = 8” on centerline

- Incline/decline modules up to 30 degrees

- Low friction, friction insert and roller top chain options

The AquaGard 7100 Series Stainless Steel Table Top Chain Conveyor is built to exact customer specifications. For more information on the new AquaGard 7100 Series Stainless Steel Table Top Chain Conveyor, visit www.dornerconveyors.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!