Meat and Poultry Processing

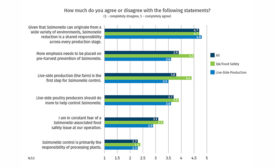

2020 Food Safety Report | Supplier's Perspective | Poultry

2020 Food Safety Report | Cold-Chain Solutions

Leverage outside help to maximize food safety

Third-party solutions providers can help processors maximize food safety and consumer reach.

Read More

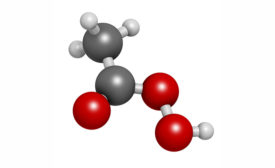

2020 Food Safety Report | Science & Technology

The chemistry of peracetic acid

March 9, 2020

2020 Food Safety Report | Supplier's Perspective | Equipment

Energy-efficient wash-down motors make dramatic impact

Read More2020 Food Safety Report | Supplier's Perspective | Standards

Are you ready for new FSIS performance standards?

Read MoreMeat & Poultry: The right tech (to) blend

Product quality and consistency depends on the proper selection and use of equipment that adds uniformity to meat and poultry products.

Read More

Livestock production on point in 2020

Barring any unforeseen circumstances, meat and poultry production and prices should be steady.

Read More

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing